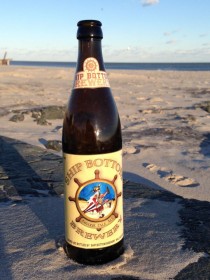

Craft beer is an art and yet we don’t always know the “painter” of each particular masterpiece. For the ultimate craft beer lover, bouncing from one brewery to the next, it would be quite a challenge to keep history tabs on each individual glass consumed. However, it’s not a hopeless cause if taken one step at a time. In fact, you’ll find many stories nestled in those final sips, like Rob Zarko’s from Ship Bottom Brewery. PA Eats’s Managing Editor Jim Breslin took time to dissect this nano-brewery’s background and found that Rob had nothing less than fascinating info to share about his garage brewing venture.

Craft beer is an art and yet we don’t always know the “painter” of each particular masterpiece. For the ultimate craft beer lover, bouncing from one brewery to the next, it would be quite a challenge to keep history tabs on each individual glass consumed. However, it’s not a hopeless cause if taken one step at a time. In fact, you’ll find many stories nestled in those final sips, like Rob Zarko’s from Ship Bottom Brewery. PA Eats’s Managing Editor Jim Breslin took time to dissect this nano-brewery’s background and found that Rob had nothing less than fascinating info to share about his garage brewing venture.

Jim Breslin: I first met Rob at the Craft Brewer’s Festival at Iron Hill in Media, PA. There were a number of great craft brewers that you would know and love like Dogfish Head, Lancaster Brewing and many more. In addition, Pinocchio’s Beer Garden had a stand and they had this stout that was brewed by Rob Zarko who was starting Ship Bottom Brewery out of his garage. So Rob, when we met back in May and I tried some of your stout – I’ve occasionally been checking in and seeing your status – at the time you were only doing a few beers that were being sampled out of Pinocchio’s Beer Garden so I thought it’d be interesting to talk with you about your start with craft beer and the process of developing your beer. Let’s start with the origin. What got you interested in beer. What’s your background?

Rob Zarko: I guess when I was younger the standard beers were the Miller, Coors, Budweiser beers that I grew up with. My brother and I found a place along the Main Line where they had a whole brewing setup. You paid the price and brewed your own beer, came back in a couple weeks and bottled it. We looked at that option then my brother found another place called Keystone Homebrew in Montgomeryville. He was able to buy a kit. From there we picked a recipe that he was eager to try, brewed it down in Ship Bottom, New Jersey, at a beach down there. We didn’t know what we were doing. We were just kind of following instructions. One funny thing we did is we left the lid of the fermenter open and went to get something to eat. Typically that would spoil everything and contaminate the beer but everything turned out fine. From that standpoint, we developed a passion for making it and creating our own recipes. For the past 15+ years I’ve been homebrewing beer, using different recipes, honing my skills and honing the recipes. Then, the last ten years, I’ve been trying to really automate my system. It was a ten gallon system so I was trying to computer automate that and process control it. Basically, that equals better beer. Over the last two years, friends and family really pushed me to start a brewery. With the money and time I was spending home brewing it made sense to move forward and give it a shot.

J: So from that point, you’ve been brewing basically out of your house. How much in the past two years have you been selling? How much has been available to the public?

R: So the last two years, we’ve actually incorporated Ship Bottom Brewery on May of 2011 and then for the last year and a half or so we’ve been trying to get licensing. I looked on the internet to figure out how we wanted to do it, tried reading multiple books to see what I was going to have to do to get into the marketplace. I noticed there were a couple other companies that were starting out of their garages or out of their houses. They would email the owners of breweries and ask how they got started and if it was even possible to do such a thing in their area. So I discovered that I needed to get local approval from my township, then state and federal approval. The funny thing is, there isn’t a book written on how to do this and go through all the processes. It’s learning under fire. You really don’t know what’s going to happen. You just keep trying and trying and trying.

R: So the last two years, we’ve actually incorporated Ship Bottom Brewery on May of 2011 and then for the last year and a half or so we’ve been trying to get licensing. I looked on the internet to figure out how we wanted to do it, tried reading multiple books to see what I was going to have to do to get into the marketplace. I noticed there were a couple other companies that were starting out of their garages or out of their houses. They would email the owners of breweries and ask how they got started and if it was even possible to do such a thing in their area. So I discovered that I needed to get local approval from my township, then state and federal approval. The funny thing is, there isn’t a book written on how to do this and go through all the processes. It’s learning under fire. You really don’t know what’s going to happen. You just keep trying and trying and trying.

J: It sounds like it might be comparable to somebody that starts baking out of their home. If they want to start selling out of their home they have to have a licensed kitchen.

R: Yes, it would be very comparable to that. It’s similar because I had to go through the same process with the FDA and get everything approved by the FDA. I have inspections from the local government and state inspections from the Liquor Control Board. There was a background check, facility check, and check on the equipment so I had to go through everything to get that done.

J: Now how many beers have you brewed that are available to the public?

J: Now how many beers have you brewed that are available to the public?

R: Well right now we received our licensing from the state and federal level and now we have to go through label approval. Part of that is, if it’s a beer that’s a non-standard beer – standard beers contain barley, hops, water and yeast – anything other than that like spices, we have to go through a formality process. Like our stout, our barrel-aged beers, our pumpkin ales and our hefeweizen that we use tropical fruits in, we’re waiting for approval on those. But our standard beers like our pale ales and IPAs will be available in January and you’ll be able to pick them up at Pinocchio’s Beer Garden in Media, PA right away.

J: Okay, so Pinocchio’s it is. Obviously, those guys [at Pinocchio’s] have been an early supporter of you. What are you hoping to deliver there? Is it draft? Is it a sixtel?

R: I’ll be doing both so it’ll be a combination of draft and bottles. With the standard beers, I’ll be doing sixtels so you can get that as draft and I’ll also be doing 12 to 16 oz. bottles. Some of the barrel-aged stouts that we have, I’ll be doing the 750 ml bottles. They will be the cork-type bottle. One of them – the stout’s an oatmeal chocolate coffee stout and we age it with bacon and maple syrup, then put it in a whiskey barrel – that will be one of the specialty beers. However, we recently found out, there’s a law that’s going to be enacted this January, that we’ll be able to sell at local farmer’s markets. We’ll bring drafts there every Thursday to the Media Farmer’s Market and have growler fills. We’ll also have specialty bottles that we’ll be selling to the public there.

J: Wow! That sounds great. West Chester has a farmer’s market too, you know?

R: [laughs] Yes, so I’ll have to look into West Chester too.

J: Oh yeah, there are tons of markets. West Goshen, Kennett Square….

R: It’s a very nice retail space for us and it really got pushed by the bigger breweries. I belong to the Brewer’s Association, and there’s one for the state of Pennsylvania and they’ve really been lobbying with the state to help the little breweries out. For me, with my system it really makes sense. Basically, what I have is the two barrel system which makes 60 gallons of beer at a time. From there, right now what we’re doing through our branding stage is we’re going to have limited supply at various outlets. I don’t want to say we’re going to have it everywhere and then we don’t and people get mad so it’s going to be at one or two places like Pinocchio’s, Quotations, the Farmer’s Market and the occasional bar.

R: It’s a very nice retail space for us and it really got pushed by the bigger breweries. I belong to the Brewer’s Association, and there’s one for the state of Pennsylvania and they’ve really been lobbying with the state to help the little breweries out. For me, with my system it really makes sense. Basically, what I have is the two barrel system which makes 60 gallons of beer at a time. From there, right now what we’re doing through our branding stage is we’re going to have limited supply at various outlets. I don’t want to say we’re going to have it everywhere and then we don’t and people get mad so it’s going to be at one or two places like Pinocchio’s, Quotations, the Farmer’s Market and the occasional bar.

J: Well I’m looking forward to trying these when they come out in January. I had a taste at the Craft Brewer’s Festival at Iron Hill in Media back in the Spring and I’d love to get more.

R: I’ll make it work.

J: Thank you so much for taking the time to talk to us about the brewing process. I wish you the best of luck at Ship Bottom Brewery and hope to be toasting a beer with you sometime in 2013.

R: Thanks Jim. I’m looking forward to it!

Photographs courtesy of Ship Bottom Brewery.